- 宇都宮キャンパス

理工学部 機械・精密システム工学科

- 宇都宮キャンパス

機械・精密システム工学科は、2025年3月で募集を停止しています

幅広い知識と新時代に対応する

応用力を身につけます

機械・精密システム工学科では、実学に根ざしたものづくりへの興味や意欲を高めるため、一人に1台ずつ使える最新の3D-CADソフトや、自動車整備実習場など、学びの環境を充実させています。徹底した少人数指導・分かりやすい授業により、幅広い基礎知識と新たな時代に対応する応用力を習得したエンジニアを育成します。

広い視野と教養を身につけるために人文科学、社会科学系科目、外国語科目などを学びながら、同時に工学的な基礎となる数理的基礎、機械工学の基礎理論、機械の設計、製作、制御に関する科目を学びます。卒業研究では技術者に必要な課題発見能力、問題解決能力、コミュニケーション能力、文章表現力などを身につけていきます。

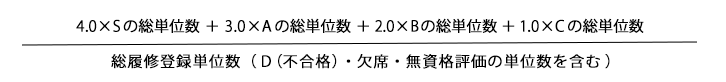

GPA(Grade Point Average)制度の導入の趣旨は、1. 学部として統一した基準を作成すること、2. 公平性に優れた基準であること、3. 国際的に通用する基準であることとし、学修の成果をGPAという客観的な数値で評価するものです。またこの制度は、外国の多くの大学が採用している成績評価制度に概ね準拠しており、海外留学、海外の大学院進学、外資系企業への就職などの際に、学力を証明する指標として国際化に対応した成績評価制度となっています。

| 区分 | 評価 | GPA | 成績評価基準 | 評価内容 |

|---|---|---|---|---|

| 合格 | S | 4.0 | 90点以上 | 非常に優れた成績を表します |

| A | 3.0 | 80点台 | 優れた成績を表します | |

| B | 2.0 | 70点台 | 妥当と認められる成績を表します | |

| C | 1.0 | 60点台 | 合格と認められる最低限の成績を表します | |

| 不合格 | D | 0.0 | 60点未満 不合格 | 合格と認められる最低限の成績に達していないことを表します |

| 欠席 | 0.0 | 試験を欠席 | 当該授業の試験の未受験やレポート等の未提出を表します | |

| 無資格 | 0.0 | 受験資格なし | 当該授業の出席日数不足により受験資格がない、または履修放棄したことを表します |

| 授業の方法 | 授業時間 | 準備学習(予習、復習) |

|---|---|---|

| 講義・演習 | 15時間~30時間 | 30時間~15時間 |

| 実験・実習・実技 | 30時間~45時間 | 15時間 |

単位の取得

単位は、各学期のはじめに履修登録を行い、授業に出席し、必要な準備学習を行い試験に合格すれば取得できます。大学の単位認定は、授業時間数が基礎となります。原則として授業時間数の2/3以上出席しなければ、試験を受ける資格がありません。授業への出席を第一に心がけてください。

卒業するためには、4年以上在学し124単位以上修得しなければなりません。また、卒業に必要な最低単位数の内訳は、学科・入学年度で異なります。

| 科目区分 | 単位数 | |||||

|---|---|---|---|---|---|---|

| 必修科目 | 総合基礎科目 | 8 | ||||

| 専門基礎科目 | 34 | |||||

| 選択必修 | 専門基礎科目 専門科目 | 36 | 6※ | |||

| 選択科目 | 総合基礎科目 | 46 | 8以上 | |||

| 専門基礎科目 専門科目 | 22以上 | |||||

| 卒業に必要な単位数 | 124 | |||||

選択科目は、「総合基礎科目」「専門基礎科目・専門科目」とも上表に示した単位数以上を修得し、その合計が各学科の指定した単位数を超えるようにすること。

総合基礎科目の選択科目は最大24単位までが卒業に有効な単位数となります。