西口直浩研究室

工作機械は、機械を作る機械「マザーマシン」と呼ばれており、さまざまな製品の生産に用いられています。その中でも、数値制御工作機械いわゆるNC工作機械は、幅広い分野の生産工程で活用されており、身の周りの製品でNC工作機械が関係していない製品を探す方が難しいほどです。近年、これら身の周りの製品市場において、市場ニーズの変化に伴う製品の多様化や世界市場における競争の激化、技術者不足といった問題が、国内製造業を取巻く環境を厳しくしています。当研究室では、これらの課題に対応するため、NC工作機械およびそれを取巻く生産設備の、高速・高精度・高能率化および汎用性向上の技術に関する研究開発に取り組んでいます。

| 教員名・所属 | 西口直浩 / 総合理工学科 機械・航空宇宙コース |

|---|---|

| 専門分野 | 生産システム、メカトロニクス |

| 研究テーマ | 加工面への誤差の転写特性に基づく面品位向上技術に関する研究 |

| 研究キーワード | 工作機械、5軸制御加工、CAD・CAM、生産システム |

| 教員紹介URL | https://www3.med.teikyo-u.ac.jp/profile/ja.5a949c4a7dd2f647.html |

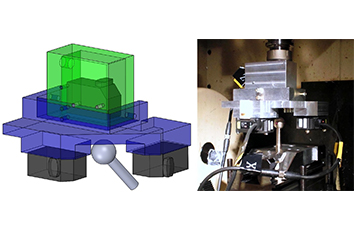

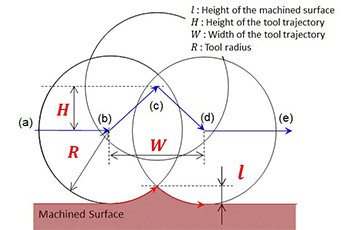

我々の身の回りにある多くの製品、特に車やプラスチック製品の生産過程では、「金型」が用いられています。この金型の製造過程には「設計」「NC工作機械による加工」「磨き」などが含まれていますが、その工程の多くを占める「磨き」作業は、NC工作機械による加工結果の影響を大きく受けます。そこで、この「磨き工程」の工数を削減するため、NC工作機械の高速・高精度化に関する研究・開発がこれまでも活発に行われています。本研究では、これらNC工作機械への要望に大きく寄与する送り軸の高速・高精度化に注目し、その測定装置と運動特性を評価するための測定技術に関する研究・開発に取り組んでいます。

本研究では、NC工作機械の送り軸運動誤差が加工面に対しどのような影響を及ぼすのか、その転写特性に注目し調査を行っています。ここでは、送り軸の運動方向反転時における運動誤差に注目し、その加工面への転写特性について調査を行いました。その結果、加工面に対し凹形状の運動誤差に対し、凸形状となる運動誤差は加工面へ転写されづらいことが分かりました。こういったさまざまな送り軸の運動特性と加工面への転写特性の調査を進めることで、運動誤差による加工誤差を効率的に補正する機能の開発に取り組んでいます。