- Important Notices

Topics Announcements from Teikyo University

Activities Teikyo University Initiatives

Education and Research

-

Professor Shibata's research group has revealed that potassium balance in the blood is maintained by cooperation between red blood cells and the kidneys via the mechanical sensor Piezo1.

Professor Shibata's research group has revealed that potassium balance in the blood is maintained by cooperation between red blood cells and the kidneys via the mechanical sensor Piezo1. -

A student from our university won the Commissioner of the Agency for Sports' Award at the "Student Competition 2025" hosted by the Agency for Sports

A student from our university won the Commissioner of the Agency for Sports' Award at the "Student Competition 2025" hosted by the Agency for Sports -

Department of Tourism Management exhibited at Tama Future Collaboration EXPO 2025

Department of Tourism Management exhibited at Tama Future Collaboration EXPO 2025

Clubs and Circles

International Exchange

Social/Community Engagement

Media

-

Daiki Yarita from Ekiden (Road Relay) Club will appear on Nippon Cultural Broadcasting's "The Road to Hakone Ekiden - A Story of the Tasuki and Bonds"

Daiki Yarita from Ekiden (Road Relay) Club will appear on Nippon Cultural Broadcasting's "The Road to Hakone Ekiden - A Story of the Tasuki and Bonds" -

We have added issue 134 of our newsletter, Flair, entitled "Cold Weather Life. Warm Living."

We have added issue 134 of our newsletter, Flair, entitled "Cold Weather Life. Warm Living." -

Associate Professor Tomohiro Saeki from Department of History will appear on BS11's "Great Men: Lessons from Defeat"

Associate Professor Tomohiro Saeki from Department of History will appear on BS11's "Great Men: Lessons from Defeat"

Others

-

Faculty of Education Department of Elementary Education Education, has been certified as a junior high and high school teacher training Elementary Education Course for Japanese language, mathematics, and health and physical education.

Faculty of Education Department of Elementary Education Education, has been certified as a junior high and high school teacher training Elementary Education Course for Japanese language, mathematics, and health and physical education. -

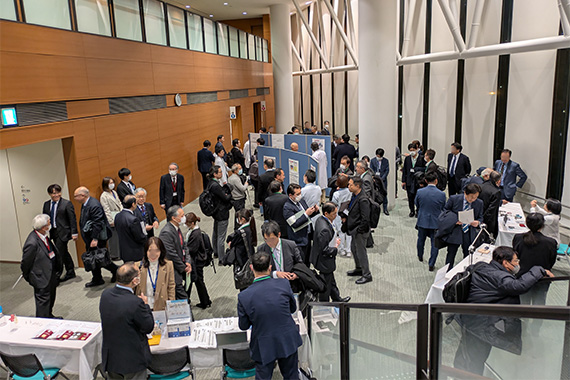

Teikyo University School of Medicine Honorary Professor Award Ceremony Held

Teikyo University School of Medicine Honorary Professor Award Ceremony Held -

Campus illumination lighting ceremony 2025 held

Campus illumination lighting ceremony 2025 held

- 2026.01.14Admission Info

- 2026.01.14Admission Info

- 2025.11.12Admission Info

Event Event information of Teikyo University

-

- Free

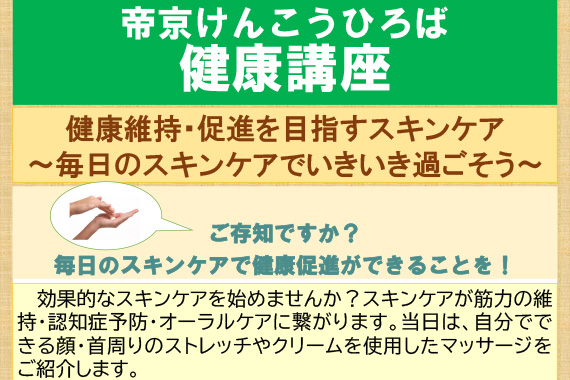

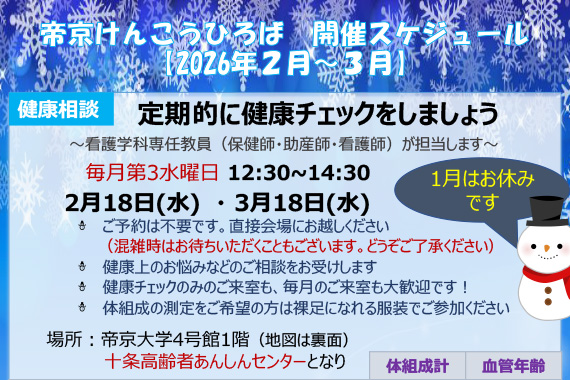

- Teikyo Kenko Hiroba

- Itabashi Campus

-

- Free

- Hachioji Campus

- Advance application required

-

- Advance application required

- Kasumigaseki Campus

- Okinaga Research Institute

-

- Free

- Hachioji Campus

- Advance application required

-

- Free

- Itabashi Campus

- No advance application required

-

- Free

- Itabashi Campus

- No advance application required

-

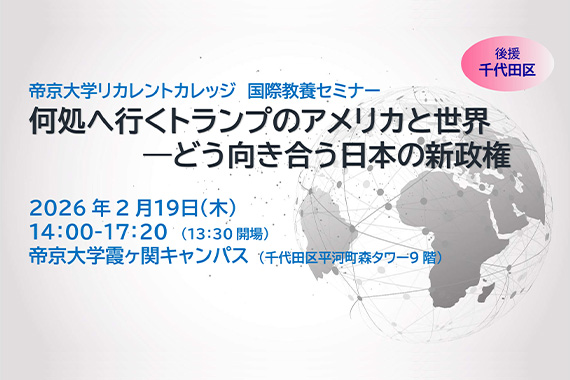

- Free

- Recurrent College

- Kasumigaseki Campus

-

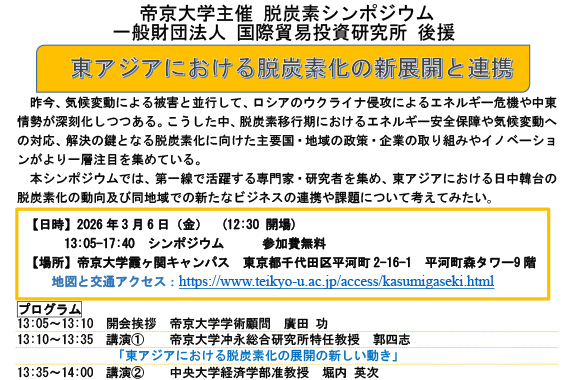

- Advance application required

- Kasumigaseki Campus

- No entry fee